Preparation for Waving

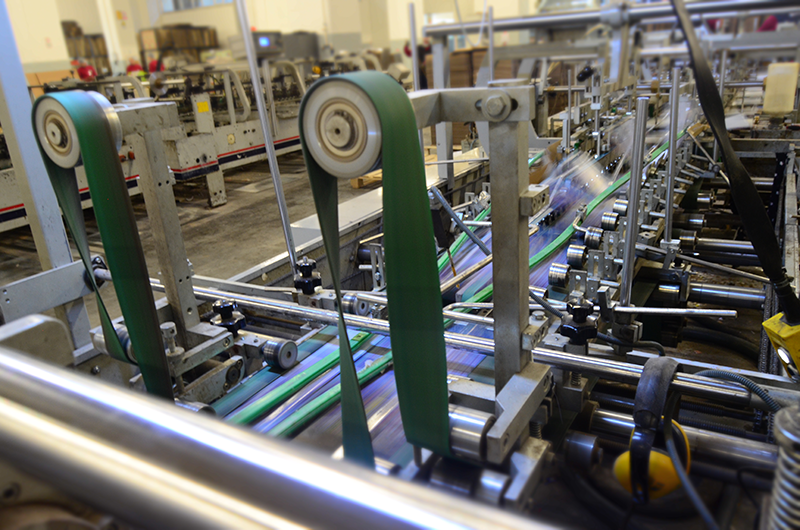

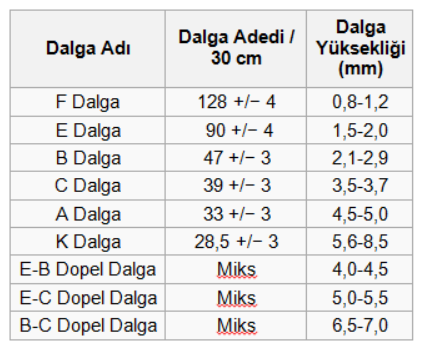

Corrugated preparations begin with combining incoming orders according to the cutting size on the corrugated line. Combinations of 2 or 3 are most common. The most preferred production corrugated sizes are 132 cm or 183 cm. Correct combination work is very important to minimize fire rates. ATEŞLER AMBALAJ can produce corrugated cardboard in different types depending on the wave type. E Wave, B Wave, C Wave, and combinations of these used together in double-layer products are prepared. E-B Wave double-layer, E-C Wave double-layer, and B-C Wave double-layer combinations can be chosen based on the required strength and protective properties. Corrugation types are classified based on the height of each corrugation, the number of corrugations within a specified length, and international standards. For example, an E-flute product has a height of 1.5-2 mm, while a C-flute product has a height of 3.5-3.7 mm.

Corrugated production using 100% recyclable cardboard paper is an environmentally friendly material type with numerous advantages. Linerboard Testliner, used as the carrier of the corrugated layer, is the name given to the carrier paper used on the inner and outer sides, which is based on recycled paper. It can be white on the upper surface or brown in tone, depending on the material. Linerboard Kraftliner is the name given to the carrier produced from the first cellulose-based product paper. By definition, it involves obtaining more than 80% of its fibers through the application of chemical sulfate or soda. It is available in white-faced or brown-faced versions. Straw paper fluting, prepared using a mixture of straw and recycled paper, is used in wave production. NSSC (Neutral Sulfite Semi-Chemical) fluting wave, specially treated for cold storage products, is used for its resistance to moisture and heat. The product must be produced using a semi-chemical process, with over 65% of the fibers being unbleached hardwood fibers. Products are selected through BST Burst Tests and CMT Surface Crush Tests to ensure the most suitable production for our customers' needs.