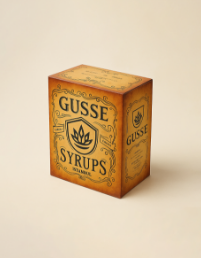

Corrugated Box

Corrugated boxes and cartons are manufactured after selecting the corrugated flute type and cardboard type and density, taking into consideration the type, weight, and strength requirements of the material to be transported, in order to provide transport strength and ease of use. After products are packaged in film, foil, or boxes, these corrugated cardboard boxes or containers, which are used by placing multiple items inside, are crucial for product protection, ease of transportation and storage, and brand emphasis.

Corrugated cardboard boxes and containers are produced using 100% recyclable materials. The strength values of the cardboard box vary depending on the following mechanical wave characteristics.

To achieve the desired strength characteristics with corrugated waves, the corrugated layer can be selected as single-layer or double-layer.

The linerboard used as the carrier for the corrugated layer is called Testliner, which is a recycled paper-based material used for the inner and outer surfaces. It can be white on top or brown in tone, depending on the material. In Europe, this paper is referred to as Wellenstoff.

Linerboard Kraftliner is the name given to the carrier produced from cellulose-based primary paper. By definition, it involves obtaining more than 80% of its fibers through the application of chemical sulfate or soda. Imitation products are also available. It is produced with either a white or brown surface.

Straw paper fluting, made from a mixture of straw and recycled paper, is used in the production of corrugated fluting.

NSSC (Neutral Sulfite Semi Chemical) Fluting corrugated cardboard, specially treated for cold storage products, is used for its resistance to moisture and heat. It must be produced using a semi-chemical process from more than 65% unbleached hardwood fibers.

Liner papers are tested for quality using BST Burst Tests, and fluting papers are tested using CMT Surface Crush Tests. Kraftliner papers have higher burst strength than Testliner.

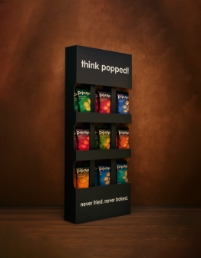

The shapes and types of boxes that can be produced according to design are unlimited. Below are examples of the most commonly used box types.

Standard box. The bottom and top flaps meet at the center of the surface halfway.

Fully covered box. The bottom and top flaps fully cover the surface, creating a double-layered closure.

Overlapping flapped box. The bottom and top flaps are applied in an overlapping manner, extending beyond the halfway point of the surface.

Bottom Standard Lid Half Box. Only the bottom section lids meet at the center of the surface halfway.

Center-closing full lid box. The top and bottom lids meet at the center of the surface halfway, with the lid lengths on the width and height sides being different to meet at the center on both sides.

Sliding Lid Box. The top surface has a single lid that locks or unlocks by sliding over the side of the lid, and the bottom surface can have a full closure, a special cut for manual closure, or an automatic closure with adhesive.

Telescopic or Tray Boxes. These are two-piece boxes consisting of a base and an external lid that overlap each other. There are different models where the lid fully covers the box or is only used as a snap-on lid. A double-sided external covering lid can also be used.

Foldable Box with Fixed Base. These are boxes with a fixed base that fold around the product. The five-sided foldable box is a widely used model. There are also models with reverse-folding side panels and locking mechanisms.

Cardboard boxes can also be printed with one or more colors to identify the box contents, manufacturer, box producer, and especially the barcode information of the distributed product.

Corrugated cardboard boxes are an important packaging material that is widely preferred due to their durability, versatility, light weight, suitability for special designs, and protective properties, as well as being an environmentally friendly and sustainable material.

The FEFCO European Corrugated Cardboard Manufacturers Federation, one of the organizations that sets standards for corrugated boxes, has defined many box designs and design features.